The plate rolling industry is witnessing a transformative wave of innovations, ranging from variable geometry plate rolls to specialized plate rolling machine attachments. These advancements are not only changing the way metal plates are bent but also enhancing the overall efficiency and maintenance of plate rolling machines.

Variable Geometry Plate Rolls: Precision and Versatility

Variable geometry plate rolls are at the forefront of precision and versatility in plate bending. These machines feature adjustable roll configurations, which can be tailored to the specific bending requirements of different projects. By providing flexibility in plate geometry, they offer new opportunities for diverse applications across industries.

Section Bending Machines: Beyond Flat Plates

Section bending machines are expanding the capabilities of plate rolling by bending various sections such as angles, channels, and beams. While traditional Plate Rolling Machines excel in bending flat sheets, section bending machines add a new dimension by curving structural elements, making them invaluable for applications like metal construction and fabrication.

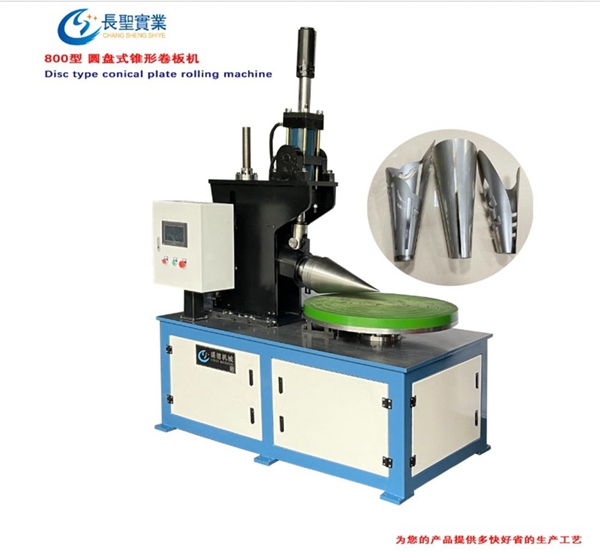

Plate Roll Attachments: Enhancing Capabilities

Plate rolling machine attachments are custom-designed accessories that enhance machine capabilities. They offer a cost-effective way to expand the functionality of plate rolling equipment. Attachments can include devices for conical rolling, pre-bending, or even special tooling for unique projects, providing solutions that cater to specific industry needs.

Plate Rolling Machine Manufacturers: Leaders in Innovation

Plate rolling machine manufacturers play a pivotal role in driving innovation within the industry. They continually strive to improve machine designs, incorporate cutting-edge technology, and ensure that their products meet the evolving demands of various sectors. These manufacturers are the driving force behind the industry's progress.

Plate Rolling Machine Maintenance: Prolonging Machine Life

Maintenance is a critical aspect of ensuring the longevity and efficiency of Plate Rolling Machines. Regular maintenance routines and services help keep the equipment in optimal working condition, reducing downtime and repair costs. Proper care and maintenance extend the life of these machines, ensuring their reliability.

As the plate rolling industry embraces variable geometry plate rolls, section bending machines, specialized attachments, and prioritizes maintenance, it paves the way for an exciting future. These innovations not only enhance the efficiency of plate bending but also increase the range of applications, making plate rolling a dynamic and evolving field.