In the world of sheet metal fabrication, plate bending and rolling are fundamental processes that have seen remarkable advancements over the years. Key innovations include the utilization of CNC plate rolling machines, three-roll and four-roll plate bending machines, and the adoption of hydraulic systems for precise control.

CNC plate rolling machines: Precision and Automation

Enhancing Efficiency and Precision

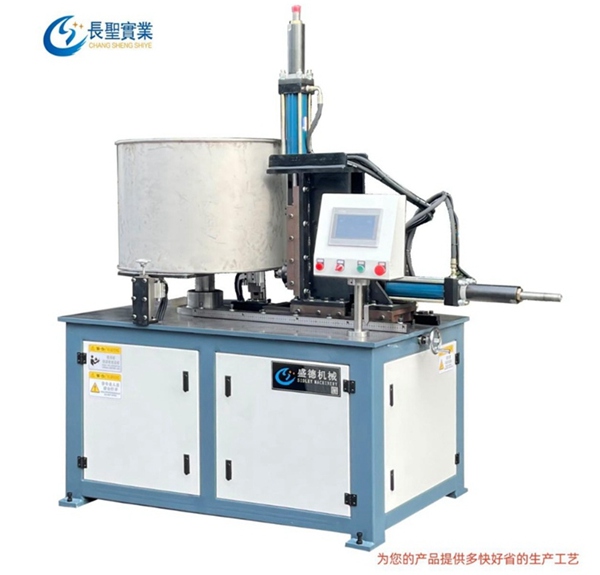

CNC Plate Rolling Machines have revolutionized the industry by offering exceptional precision and automation. These machines are equipped with computer numerical control systems, allowing for accurate and repeatable bending of various sheet metal materials. The use of CNC technology ensures that complex bending tasks can be accomplished with ease, making it a valuable asset in modern sheet metal fabrication.

Three-Roll Plate Bending Machines: Versatility and Efficiency

The Power of Triple Rolls

Three-roll plate bending machines have become synonymous with versatility and efficiency. They employ three rolls, with the top roll providing the necessary pressure for bending. These machines are particularly adept at handling large and thick plates. Their simple yet effective design makes them an indispensable tool in various industries, including shipbuilding and construction.

Four-Roll Plate Bending Machines: Precision and Control

Superior Precision in Bending

For even greater precision and control, four-roll plate bending machines are the go-to choice. The additional roll in these machines allows for more accurate and consistent bending. They are ideal for projects that demand the utmost accuracy, such as the production of pressure vessels and cylindrical tanks.

Hydraulic Plate Rolling Machines: Power and Flexibility

Harnessing Hydraulic Force

Hydraulic plate rolling machines have played a pivotal role in achieving precise bends. By utilizing hydraulic systems, these machines apply the necessary force to bend the metal sheets. The hydraulic control ensures a smooth and controlled bending process, making them highly adaptable for a wide range of applications.

The Future of Plate Bending

The ongoing advancements in plate bending technology, including CNC systems, three-roll and four-roll machines, and hydraulic controls, reflect the industry's commitment to delivering quality and precision in sheet metal fabrication. These innovations are driving efficiency and expanding the possibilities in the field of plate bending, ensuring that it continues to evolve and meet the demands of various industries.