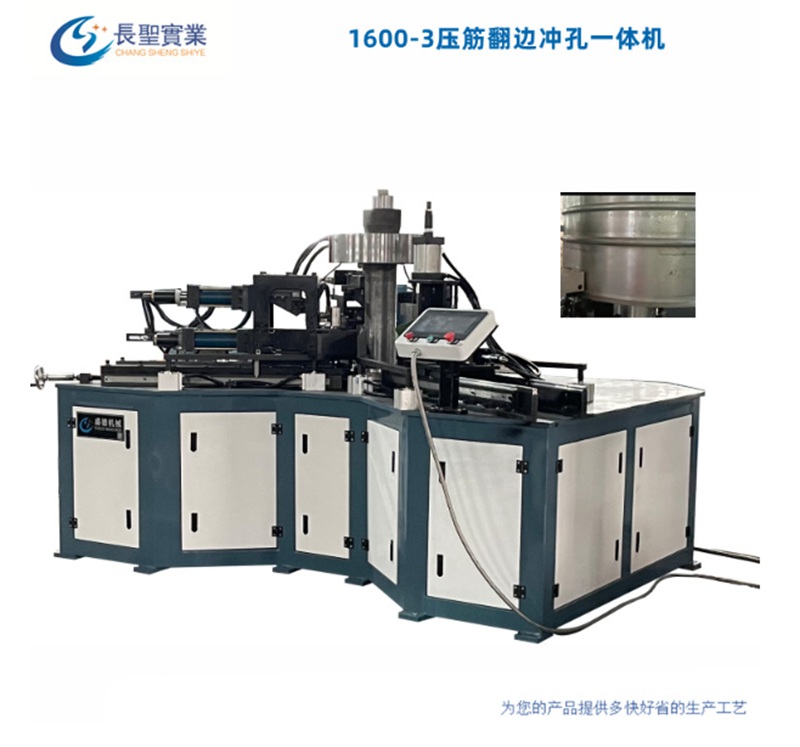

A Crimping and Flanging Punching Machine is a versatile metalworking tool that is designed to perform both crimping and flanging operations. The machine is commonly used in a variety of industries, such as HVAC, automotive, and aerospace. Flanging Machine exporters and Flanging Machine factories have been producing high-quality machines to meet the increasing demands from metalworking businesses.

The machine works by clamping a metal sheet between two dies and then applying pressure to create a crimp or flange. The process is automated, and the machine can produce consistent results, making it an ideal solution for high-volume production.

Flanging Machine exporters and Flanging Machine factories have been providing efficient and reliable machines to their customers around the world. This allows metalworking businesses to operate with precision and speed, delivering high-quality results to their customers. The Crimping and Flanging Punching Machine is an essential tool for any metalworking business that requires crimping and flanging operations.

1. Power supply type: 380v three-phase 5-wire

2. Equipment weight: 4.8t

3. Total power of the equipment: 23kw

4. Equipment function: edge pulling, punching, bar pressing

5. Equipment processing size: 250-1600MM

6. Equipment processing thickness: 0.6-4mm

7. Equipment size: flanged flange edge within 200mm from the center of the bar

8. Control mode: numerical control

9. Number of punching holes: 0-100 arbitrary

10. Equipment specifications: 2600x2000x1700mm