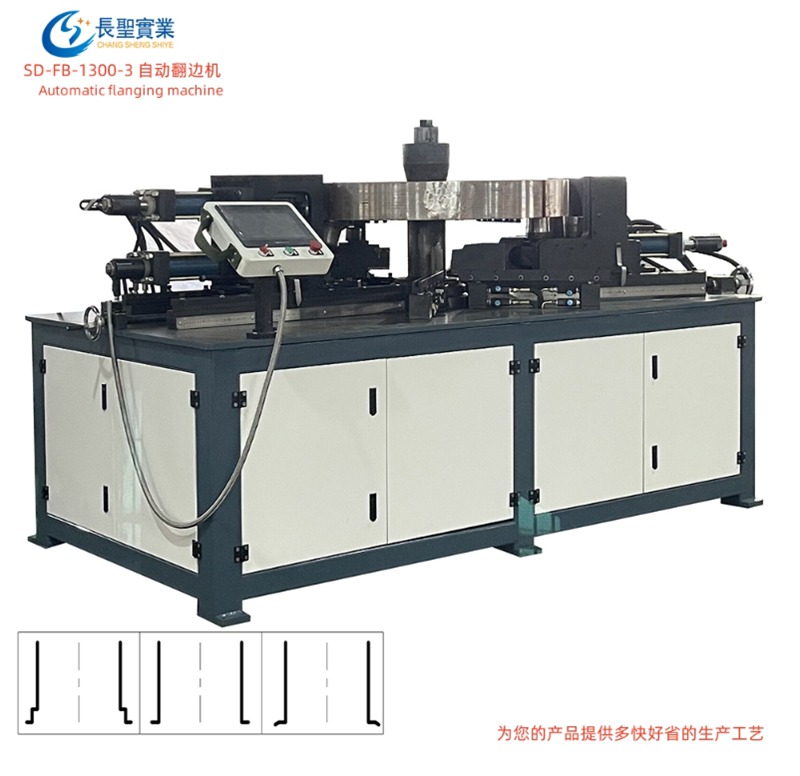

The Automatic Flanging Machine is an innovative piece of equipment designed for sheet metal flanging. It is a versatile and efficient tool that is ideal for various industries, including automotive, aerospace, and construction. The machine features advanced capabilities such as precision punching, remote control, and variable speed, enabling it to produce high-quality flanges quickly and reliably. Companies looking for a customized solution can opt for a bespoke Flanging Machine tailored to meet their specific dimensions and project requirements. For those seeking a private label Flanging Machine, the Automatic Flanging Machine is an excellent choice as it can be branded with a company logo and marketed as its own product. Overall, the Automatic Flanging Machine is an excellent investment for any industry that requires high-quality flanges.

1. Each work station in and out are driven by servo motors;

2. Forming configuration preservation function, when replacing the workpiece only need to call out the program (greatly reducing the difficulty of debugging, saving debugging time and enhancing the consistency of the production products).

3. Increase the pre-bending function when rolling the edge, when rolling stainless steel, improve the finished product rate.

4. Annual production capacity of about 100 units of this type of models, can provide strong technical support.

5. Support material device adopts oil cylinder support, with strong support force and small radial swing when the workpiece is rotating.

6. The flange width adjustment adopts step type module, the flanging width is more stable and the adjustment type saves more time.

7. Adopt corner type star reducer, make the machine higher and lower, more use operation.

1. Power supply type: 380v three-phase 5-wire

2. Equipment weight: 4.8t

3. Total power of the equipment: 15kw

4. Equipment function: secondary drawing edge Flanging edge

5. Equipment processing size: 250-1300MM

6. Equipment processing thickness: 0.6-4mm

7. Control mode: CNC

8. Number of punching holes: 0-100 arbitrary

9. Equipment specifications: 2600x2000x1700mm