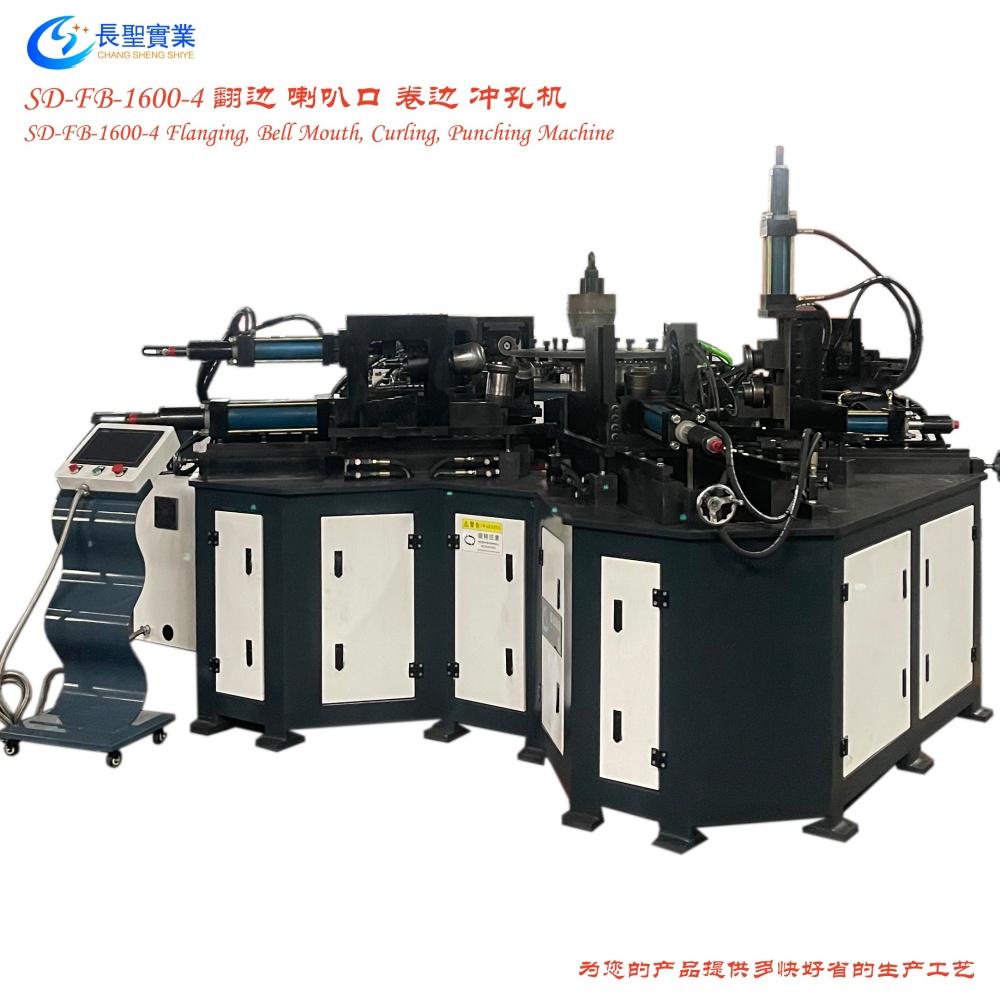

Equipment functions: flanging, punching, curling, pre-bending, pressing

Equipment features:

1. Each station is driven by a servo motor for advance and retreat;

2. The forming configuration save function only requires calling out the program when changing the workpiece (greatly reducing the difficulty of debugging, saving debugging time, and enhancing the consistency of production products).

3. The pre-bending function is added when curling, and the yield rate is improved when rolling stainless steel.

4. The spindle is equipped with a high-power servo motor and a star reducer to improve the punching efficiency and the accuracy of the indexing.

5. This type of machine with an annual output of about 100 units can provide strong technical support.

6. The support device adopts a cylinder support, which has strong support force and small radial swing when the workpiece rotates.

7. The flange width adjustment adopts a step-type module, the flanging width is more stable, and the adjustment type saves time.

8. The corner star reducer is adopted to make the machine lower and more convenient to operate.

Equipment processing parameters:.

1. Flanging product diameter: 250-1600MM

2. Flanging product thickness: 0.8-4MM

3. Flanging height: 100-1800MM

4. Equipment specifications: 2400x2000x1700 (MM)

5. Total equipment power: 26KW

6. Equipment weight: 4.6t

7. Punching diameter: 5-20MM

Punching accuracy range: plus or minus 1MM