Power type AC 380v three-phase four-wire

Workpiece clamping method Hydraulic chuck

Total equipment power 48kw

Maximum spinning product diameter 600

Spindle speed 0-1000 rpm

Spinning thickness (iron plate) 4

Air pressure 0.5-0.8Mpa

Spinning thickness (aluminum plate) 6MM

Spindle center height 6000MM

Spinning thickness (stainless steel plate) 2.5

Axial stroke 800mm

Maximum spinning product height 800

Radial stroke 300MM

Pressing power Hydraulic

Tail top stroke 800mm

Control system Diens

Positioning accuracy 0.02mm

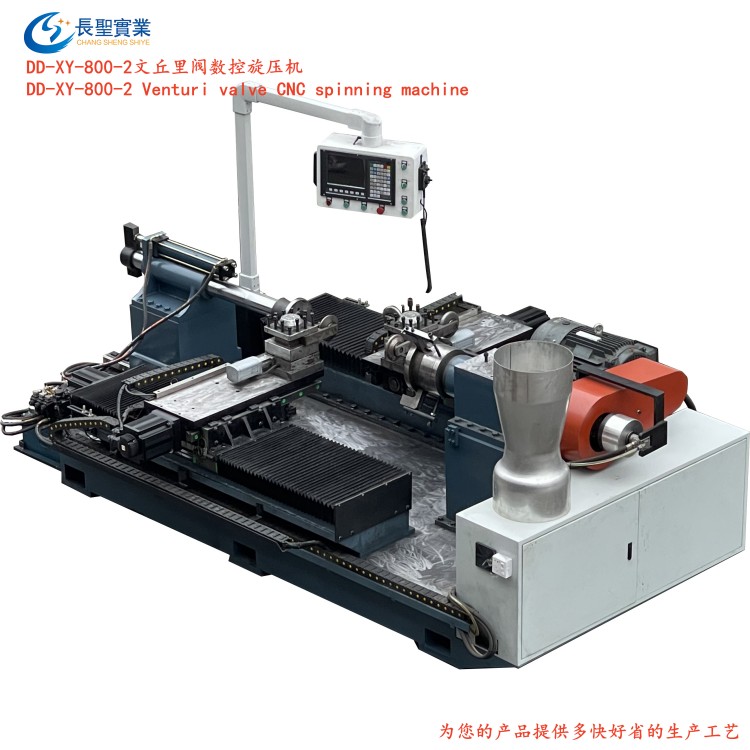

Spinning structure Horizontal

Automatic oiling system AC220V 25W1

Warranty period 1 year

Installation tool position 4+4 positions

Servo type Absolute servo

Input method Handwheel teaching/CAD guide

Equipment weight 3000KG

Appearance size of the equipment 3200x2800x1700

Mold installation thread

Application: This machine is suitable for lamps, cookers, handicrafts and other industries. It can complete the batch production of barrel-shaped, cone-shaped, parabolic-shaped, trumpet-shaped, bullet-shaped and other series of products.